Building furniture or carrying out any other fine woodworking project requires, the use of lumber with flat, straight edges and square corners. Producing this kind of lumber requires the use of a wood jointer machine.

It lets you flatten and straighten warped or irregular wood surfaces, making it suitable for your projects.

You may wonder why it’s called a jointer, not a flattener or some other name that portrays what it does just like a thickness planer.

Well, to join or glue two or more boards edge-to-edge to form a wider board, you need to flatten the edges of those boards so that they can align perfectly with each other. So, the name of the machine for making the edges of boards flat so that they can be joined or glued together is the jointer.

Just like a thickness planer machine, power jointers come equipped with different types of cutterheads powered with an electric motor. The better the quality of the cutterhead, the better the surface finish left on the wood.

It features two tables on the same plane, in-feed and out-feed tables, and a fence that guides the workpiece along the tables. The in-feed table can be adjusted below the cutterhead while the outfeed table stays level with the cutterhead.

Depending on the model, the fence can also be adjusted or beveled towards or away from the table to accommodate workpieces with flat beveled edges.

There are two main types of jointers which are:

- Benchtop and

- Cabinet or Floor Units

Benchtop jointers are portable units suitable for small workshop owners, hobbyists, or DIYers looking for a portable machine for flattening rough boards. Since they’re portable, benchtop units can also be used on a job site because you can quickly put one in the back of your truck and drive to work.

Cabinet or floor models are stationary machines meant for workshop use, but they also come in different sizes determined by the size of the motor in Horse powers and the size of the jointing tables.

The wider the table, the larger the workpiece size it can support.

Since there are different types, different manufacturers, and sizes, choosing one for your projects can be difficult.

That’s why we’ve I’ve written a buyers guide below this list to help you make the right choice.

For now, here are 7 of the best wood jointer machines we tested.

Table of Contents

1. Powermatic 54HH 6 Inch Wood Jointer

One of the most user-friendly, floor model wood jointers is this Powermatic 54HH. It’s a simple but very effective wood straightening and dimensioning machine you can use right there in your workshop.

It comes equipped with a powerful 1 HP motor which ensures it’s capable of cutting any type of wood, whether hard or soft.

Unlike most conventional wood jointers, the Powermatic 54HH features a helical cutterhead with 40 four-sided inserts, arranged in spiral-shaped rows which allow it to cut more smoothly and quietly.

Because the carbide inserts are four-sided, a nick on one edge can be fixed easily without dismantling the whole cutterhead. Simply lose the screw holding it to the cutterhead and turn it to a new side, and it’s as good as new.

With 66 inches long and 6-1/2 inch-wide infeed and outfeed tables, the Powermatic 54HH boasts one of the longest work surfaces that can accommodate large workpieces without any issue.

The infeed and outfeed tables are made of precision ground cast iron which are securely mounted on dovetail rails. These makes them very sturdy and perfectly aligned no matter how many height adjustments they go through.

Talking about adjustments, fine-tuning the Powermatic tables and fence to suit your desired measurements is easy and straightforward. There are separate levers for adjusting the infeed table, the outfeed table and the fence, with the fence controls mounted directly in the center for easy access.

The fence is 38 inches long, and can be beveled in both directions, away from and towards the table, and there’re positive stops at 90 degrees vertical and 45 degree angle for easy set-up.

Housing the motor and cutterhead assembly is a 21×13 inch heavy-duty all-steel base cabinet, that helps elevate the table surface to a comfortable working height of 32 inches, protects the machine components and keeps it working quietly.

2. Grizzly Industrial G0858 8 Inch Parallelogram Wood Jointer

The 8 inch Grizzly Industrial G0858 parallelogram wood jointer offers a precise workhorse for flattening boards to highest degree of precision in the workshop.

It’s a heavy duty piece of machinery with all the necessary components and features needed to dimension and flatten rough lumber for fine woodworking purposes.

Powering it is a 3 HP, 230V single-phase motor, which ensures it cuts through any type of wood easily no matter its hardness.

Apart from the heavy duty motor, the helical style cutterhead also helps cut through materials easily without bugging down the motor, producing a much smoother cut in the process and also produces less noise compared to similar cutterheads with straight knives.

The helical cutterhead has 4 rows of 36 four-sided inserts that are indexable. Which means it’s more economical in the long run because each insert can easily be switched to a new side if one side gets nicked by a knot in the wood.

8 inch by 76 inch extra long precision-ground cast iron table provides adequate support for large workpieces.

The parallelogram setup of the tables ensures each table is easy to adjust for perfect alignment and overall precision of the machine and resulting work done with it.

Also featured is a cast iron fence with beveling capability and positive stops at 45, 90 and 135 degree angles. This is a cabinet machine which means it’s very heavy. That’s why it comes equipped with a built-in mobile base with non-directional casters mounted on the inside of the base to make it easy to move it around the shop.

3. PORTER-CABLE PC160JT Variable Speed 6 inch Benchtop Jointer

Porter Cable’s 6 inch benchtop jointer makes use of a 2 straight knife cutterhead but it produces one of the best results you’ll ever get with a portable machine like this.

The 2 knife cutterhead makes use of a jack screw knife levelling arrangement and a built-in cutterhead lock which makes it easy to adjust the knives or replace them when necessary.

The table is extra-large, thus providing you enough space to support and joint boards easily with it.

One important feature of the PC160JT is that it has variable speed. That means you can vary the speed depending on the amount of material you’re taking away in one pass.

If you’re taking out a lot of material, you can reduce the speed, and increase it when you’re taking out a lesser amount of the wood you’re jointing.

As far as performance go, this Porter-Cable performs flawlessly for a machine of its size. Setting it up is easy and working with it is even easier.

Related: Should You Get A Jointer Combo Machine?

4. Rikon Power Tools 20-600H Benchtop Jointer

If you’re looking for a benchtop jointer, one of the first ones you should consider is the Rikon Power Tools 20-600H.

One of the best feature of the Rikon is that it comes with a 6 row helical cutter head made up of 12 high speed steel , 2 insert cutters, which not only makes jointing boards with it super easy.

Straight knife cutterheads can be a bit noisy, but with a helical cutterhead like the one on this Rikon, you can work without disturbing the neighborhood with your jointer.

Though, you still have to wear ear protection as it’s not soundproof.

The Rikon 20-600H comes equipped with a powerful 10 Amp motor, ensuring there’s sufficient power to spin the cutter head and joint the boards you want to joint.

Every part of this Rikon benchtop jointer body is made with metal while the tables are made of machined aluminum. This all-metal body construction is good news for you because you can be sure that it’s not something very flimsy.

It’s rigid and strong, and will definitely stand the test of time with proper maintenance.

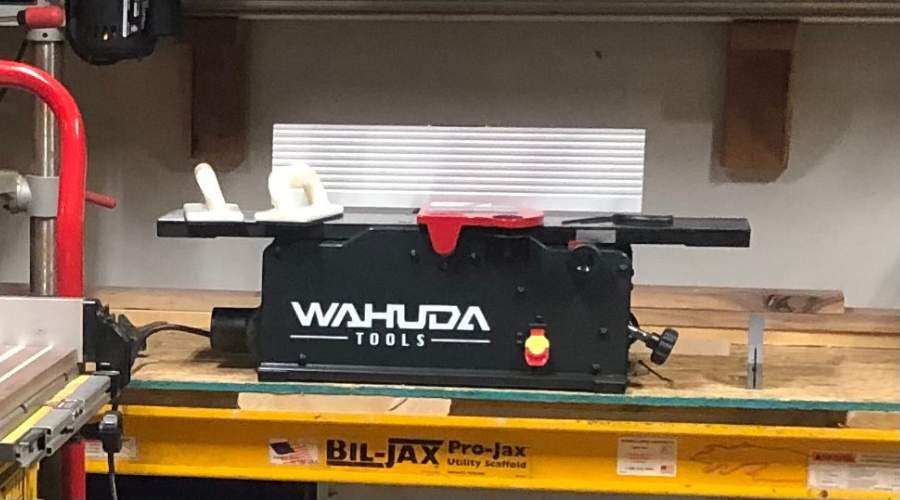

5. Wahuda 8 inch Benchtop Wood Jointer

The reason we buy wood jointers is because we want perfectly straight and aligned boards for our projects. One of the best portable jointers you can use to achieve this is the Wahuda 8 inch benchtop jointer.

Wahuda is not a very popular brand, and you may not have come across it before, but they certainly come through with most of their tools, especially the ones I’ve seen.

This Wahuda 8 inch jointer comes with all the features you need to machine perfectly sqaure boards for your projects.

Under the hood, powering the machine is a 120V motor producing a fixed speed of 12,000 volts to turn to the cutterhead.

The cutterhead itself is one of the most interesting part of the machine. It’s a spiral cutterhead with 4-sided carbide inserts, that not only ensures very smooth surfaces on your boards, but also a quiet operation of the machine.

This is an 8 inch unit, which is great for most types of jobs, but you can opt for a larger 10 inch unit or a smaller 6 inch if that’s what you want.

Overall, I think this Wahuda 8 inch benchtop jointer is the perfect machine you need for all jobsite operations. This will also be perfect for you if you’re looking for a machine that will not take up a lot of space in your already small workshop.

6. WEN JT833H 8 Inch Benchtop Jointer

Talking about the best benchtop jointers, the WEN JT833H definitely makes it into the list. It comes with all the features you need to flatten and face-joint boards efficiently.

With a 10 Amp motor, the WEN JT833H doesn’t lack in power, as it pins the cutterhead, producing 20,000 cuts per minute on your board and leaving the smoothest of finishes on it.

It’s equipped with a wide table with dimensions of 6-1/4 x 28-1/2 inches, providing enough space needed to support boards and face-joint them successfully.

With a heavy cast iron base, the WEN JT833H will never walk while flattening boards with it. It will always remain rigid and steady as you joint boards with it.

Overall, if you’re looking to choose from the best benchtop jointers, this WEN JT833H is one you should strongly consider.

7. Shop Fox W1876

The Shop Fox W1876 benchtop jointer will serve you well if you’re looking for a portable machine to plane the surface or face-joint your boards and get them square.

With a fully adjustable aluminum fence which you can adjust up to 45 degrees inwards, 90 degrees and 45 degrees outwards, you get a suitable jointing machine you can use in your small shop or jobsite comfortably.

It comes equipped with a 1-1/2 HP, 12 amp motor which spins the cutterhead at a speed of 10,000 RPM and produces up to 20,000 cuts per minute on your board.

The table is large enough and provides a wide space to support your work piece. Dust collection is very easy with the Shop Fox W1876 as it comes with a built-in dust collection fan and bag for collecting the dust produced as you work with it.

With the spring loaded blade guard always covering the cutterhead, you can work with peace of mind and safety as you use the machine.

This Shop Fox also comes with a pair of safety push blocks which you can easily use to handle workpieces to ensure safety while using the Shop Fox W1876 benchtop jointer.

In terms of negatives, changing the blades of the Shop Fox poses a little problem, but with a little time tinkering with it, you can easily get them out and replace them.

The Aluminum fence that comes with it is not the best of jointer fences, but as long as you’re not always changing the position of the fence, you’ll get it to work just fine. One positive is that, setting it up is very easy. Just follow the manual or watch a few YouTube videos if you can, and you’ll be on your way to jointing boards with it in no time.

What to Consider When Buying A Wood Jointer

If you plan to buy one of these machines soon, there are 5 crucial factors to keep in mind before making your choice.

Width capacity

The first thing you should consider before choosing any wood jointer is the width of the table or the length of the cutterhead. How wide is the table?

This width will determine the size of boards you can flatten with the machine. There are 6-inch, 8-inch, 10, 12, 14, and even 16-inch jointers.

These numbers refer to the width of the jointer table. The wider the table, the wider the stock you can flatten with the machine.

Of course, it will be fantastic to have a unit with a 16-inch table. But it will also mean you have to pay a premium for it because the wider the table, the bigger the cutterhead, and the more powerful its motor will be. All that equates to a more expensive machine overall.

For most people, an 8-inch jointer should be enough because if you’re carrying out simple projects in your home workshop, you’ll really work with rough lumber wider than 8 inches.

On the other hand, if you’re a professional woodworker and your projects require you to work with wider lumber pieces, you can consider upgrading to one with a wider table.

You can also rip down very wide lumber with a table saw to a size that can fit the jointer you have, joint them separately, and glue them back together when you’re done.

Length of the table

Another factor you must consider before choosing a power jointer is the combined length of the infeed and outfeed table.

The longer the table is, the longer the stock you can flatten with it comfortably. If a table is not long enough, you have to crosscut the lumber pieces down-to-size, so they can fit the table.

This also revolves around the capacity of the machine you choose. For example, the table of an 8-inch jointer is longer than that of 6-inch jointer, and that of a 10-inch unit is longer than that of an 8-inch machine.

So, consider the length of the infeed and outfeed table when choosing because that will determine the size of the stock it can accomodate.

Type of cutterhead

The style of cutterhead in the wood jointer is another important factor to consider. Cutterhead affects a lot of things in jointers and planers.

It affects the smoothness of the surface produced on the stock, the noise of the machine, and the ease of changing and adjusting knives in the cutterhead.

Considering this, there are two types of cutterheads you can choose from: a straight knife cutterhead and a spiral or helical-style cutterhead.

Spiral or helical-style cutterheads usually consist of several square-shaped carbide inserts arranged in spiral-shaped rows around the cutterhead. Each sharp carbide insert has four sharp edges and is fastened to the cutterhead with a screw.

During operation, only one edge of the insert comes in contact with the workpiece. So, if that edge gets nicked or gets blunt, you can simply rotate the insert to expose a new fresh edge by loosening the nut holding it to the cutterhead and retightening it after rotating the insert.

Spiral or helical cutterheads are easier to adjust, the blades or inserts are easier to change, they produce a much better finish on the stock, and they’re usually less noisy during operation than a straight knife cutterhead.

A straight knife cutterhead usually consists of 3 or 4 straight knives arranged around the cutterhead. If one gets dull or nicked, you have to loosen several nuts to remove it from the cutterhead, resharpen it, and then fasten it again to the cutterhead. You also have to adjust it properly so that it’s parallel to the table and raised to the same height as the other knives so that they match and work correctly.

You wouldn’t go through this whole process if it were a helical-style cutterhead. So the only advantage of having a straight knife cutterhead is that it’s cheaper.

Fence casting

The fence on a wood jointer machine is one of the essential part of the machine. It performs two important functions. First, it helps guide the workpiece, and second, it’s used for squaring the edges of boards to their faces.

It’s essential that the fence is tall and that it’s square to the jointer table. A tall fence will support a wider workpiece and be much more effective when squaring edges to faces.

You should also ensure that the fence is straight along the length and flat along its width. If the fence is not straight or warped in any way, it will affect the squareness of the boards you joint with it.

So, check for the squareness and flatness of the fence before buying the machine, and even after that, always use a square to check that the fence is precisely at 90 degrees to the table before using it.

Motor Access

To change or tension the belt of the jointer, you’ll have to access the motor. For some jointers, this is quite difficult because there’s not enough space to do this.

The belt tensioning mechanism is easier to use in some than others. To release and change the belt in some, you’ll have to loosen the whole motor from where it’s mounted to remove tension from it and remove the belt, replace the belt with another one, and retighten the motor.

On the other hand, some units have a single nut you can loosen to remove tension from the belt and change it if you want.

This is one essential factor you must also consider when choosing your wood jointer machine.