As a beginner, metal cutting can be quite difficult and intimidating, because out of all the different types of construction materials such as wood, bricks, concrete, metal / steel is the hardest and strongest of them all.

Unlike the other materials, it takes a lot to cut steel. In fact, it’s even harder to break it, because steel has lots of tensile strength in contrast to other building materials such as wood, bricks, and concrete.

Structural metal or steel is denser, harder, stronger and heavier. That’s why your regular wood and concrete cutting tools are not suitable for cutting it.

There are more effective metal cutting tools available, which I’m going to show you in this article. Each of the tools I’m going to describe here have their own pros and cons.

Each of these tools exist because there are different types of metal supplies used in construction such as square tubing, round tubing, round bars, rebars, sheets, plates, steel beams, flat bars, C-channel, angle iron and so on.

These supplies also come in different thickness which will require the use of different types of cutting tools and methods.

In this article, I have listed the different tools you can use for cutting metal, the type of metal supplies you can cut with each of them and the pros and cons of each tool.

Table of Contents

Snips

Snips function like scissors and are one of the best manual means of cutting sheets of metal. Just like a scissors, the user applies the force needed to shear through the sheet.

They’re usually more suitable for cutting thin sheets, so don’t go buy a snip if you’re trying to cut a thick plate, rebar or round bars. It won’t work for those.

There are 2 main types of snips which include “Thinner Snips” and “Compound Action Snips”. They’re both used for cutting sheets of metal.

However, thinner snips are less popular and are usually defined by their long handles and short blades. They’re ideal for cutting really thin sheets of metal between the range of 24 and 16 gauge like cold-rolled carbon tin.

On the other hand, compound action snips are the most popular types you’ll find in most workshops. This is because they’re more powerful, able to exert a higher force compared to thinner snips due to the compound action design of the handle linkage to the jaws.

They’re also called aviation snips because they were first developed to cut aluminum used in the construction of aircraft. Now, they used for other many other applications in the workshop, with the capacity to cut up to 18 gauge of mild steel, and 24 to 26 gauge of stainless steel.

Compound action snips comes in 3 cutting styles namely: straight cutting, left cutting and right cutting snips, each identified by the color of their handles. Straight cutting snips usually have yellow handles. They cut straight lines and wide curves both left and right.

Left cutting snips usually have red handles, and they cut both straight and tight curve lines to the left. While right cutting snips usually have green handles, and they cut both straight lines and tight curve lines to the right.

Bolt Cutter

As the name implies, bolt cutters are used for cutting bolts, they’re not limited to cutting bolts. They are also used for cutting metals of similar thickness and strength such as chains, wire mesh, rebar, padlocks and so on.

They look like bypass or anvil loppers on steroids, because instead of cutting wood, these are used for cutting steel or metals.

Just like loppers, they usually have very short blades and long handles with compound hinges which maximizes the leverage or effort applied on the handles.

Most bolt cutters usually have steel handles, but some come with fiberglass handles and are used for cutting live electric wires during rescue operations.

Metal Shears

Metal shears are either hand-powered, compressed air powered or electric powered hand operated tools for cutting sheet metal or aluminum sheets.

The snips described above are also used for cutting thin sheets, but they require human effort or elbow grease to get the job done.

Most shears on the other hand have motors or mechanisms that are powered with electricity or compressed air, thus cutting the sheet faster and allowing the tool to do most of the hard work.

Unlike snips, shears also cut thicker and harder sheet metals and aluminum used for roofing and flashing.

They can also be used for cutting sheet metal used for auto body like car fenders. A little downside is that a little bit of the sheets go to waste, because with each cut, the shears takes off about a quarter each of the material.

Hack Saw

A hack saw is one of the most common hand tools used for cutting metal. Even if you’ve never seen all the other cutters shown here in this article, it’s very likely that you already have one of these in your workshop.

Hack saws are not just for cutting sheet metal, but for cutting other types of steel supplies like rebars, roun pipes, square pipes, angle bars and so on.

It’s quite simple to use it, but obviously, it’s hand powered, that means you have to provide the effort required to cut the material. It requires repeated to and fro movement of the blade over the material being cut.

It’s not a very efficient way of cutting, but it comes in handy in several situations in the workshop and on the jobsite where other means of making the cuts might just be an overkill, or if there’re no other tools to make the cut.

Reciprocating Saw

A reciprocating saw is basically a motorized hacksaw. It can be used for cutting different types of materials, including metal of different thicknesses.

Cuts with a reciprocating saw are fast and easy, as long as you choose the right saw and use the right blade.

One main advantage of using reciprocating saws is that the blades are pretty flexible, which means they can easily access tiny spaces where other tools fail.

It also does not require a lot of setup before starting your cut, which reduces downtime, allowing the user to make cuts as quickly as possible.

Angle Grinder

An angle grinder is one of the most used metal cutting tool you’ll find in different workshops. Its main purpose is for grinding down or removing excess material from a piece using an abrasive disk attached to the spindle.

But because several other attachment or cutting wheels and discs can be attached to the spindle, it can also be used for cutting.

It finds a lot of uses in the workshop because it can be used for cutting different types of steel goods, including sheet goods, rebars, angle iron, round bars, tubing and so on.

Related: 11 Important Concrete Working Tools For Beginners

Metal Cutting Circular Saw

Metal cutting circular saws are like cold saws allow the user to carry out spark-free cuts on different types of steel materials.

These are unlike your regular circular saws for cutting wood. They come equipped with lower RPM motors to ensure safe cuts, and are equipped with special types of blades for cutting through metal efficiently.

Unlike a regular circular saw, it features a blade shield that collects all the chips and sparks produced when making cuts.

Just like an angle grinder, these circular saws can cut different types of steel, including sheet goods, tubing and even thick plates.

The only caveat is, it cannot be used for cutting curves, just straight lines.

Metal Cutting Horizontal Bandsaw

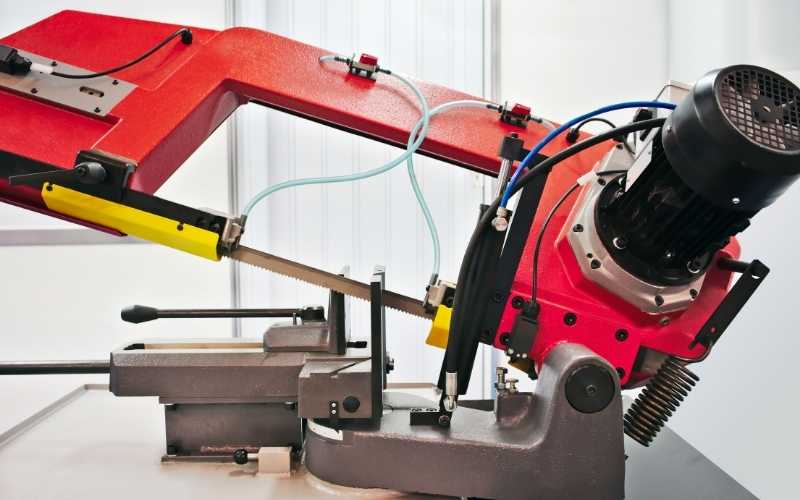

There are different types of bandsaws, but the two main types are differentiated according to their axial orientation or configuration during use. They include the vertical bandsaw and the horizontal bandsaw.

Vertical bandsaws are mostly used for cutting non-metallic materials like wood, while horizontal bandsaws are mostly found in fabrication workshop for cutting steel and similar materials.

Horizontal bandsaws comes with clamps that allow you to hold the workpiece in place while the blade cuts down through the material. Once the cut is made, the blade stops all by itself without intervention.

These have many uses in the workshop for cutting different types of steel goods like thick round bars, round tubing, square tubing, rectangular tubings, flat bars and so on.

Multitasking with a horizontal bandsaw is possible because after the setting up the saw, once it starts cutting a really thick steel bar, you can go on and carry out another task because the saw will stop automatically by itself once it cuts through the bar.

Sheet Metal Nibbler

As the name implies, a sheet metal nibbler is a power tool specifically designed for making cuts on sheet metal.

They’re usually compared to shears when cutting sheet goods, but instead of removing thin strips off the material being cut like double cut shears do, nibblers takes little half-moon chunks from it. It kind of nibbles its way through the sheet. And I think that’s where the name came from.

When cutting roofing sheets, nibblers are best for cutting across the ribs or channels of the sheet. Whereas, shears are best for cutting along it.

Chop Saw

The chop saw has been around for quite some time. It’s very similar to a compound miter saw used for cutting wood and other non-ferrous metals.

However, the chop saw is practically built for cutting different types of steel, apart from sheet goods. It’s basically a tool for crosscutting not ripping through materials.

Just like any other saw, you have to fit it with the right kind of metal cutting blade, so that it can cut through easily and safely.

For instance, most chop saws make use of abrasive disks which produce a lot of sparks. When I say a lot, I really mean a lot of sparks which can be quite scary and not safe if you’re working around a home workshop with flammables around.

If there’re not flammables around however, it will cut through any type of steel for you. You should be careful when cutting materials like aluminum with an abrasive disk on a shop saw because the aluminum clogs up the wheel which impacts the saw and is not quite safe.

Overall, as long it’s not aluminum, chops saws will crosscut through most types of steel supplies including tubing, round bars, angle iron, rebars and so on.

Thank you for this that you do, you assisted in my assignment. I love you sirs.

thanks for all that information.

You’re welcome. I’m glad you found it helpful.