Many woodworkers will agree with me that the sanding process is not the most favorite part of any woodworking project.

In fact, I’m almost certain that it’s the least favorite part of all the processes it takes to complete a woodworking, remodeling or home improvement project.

However, it’s a very important and necessary part that largely affects the final appearance or looks of the project. Hence it cannot be skipped or overlooked even though we don’t look forward to doing it.

The way forward is to look for ways to make it easier and less unpleasant. One of such ways is to use the right type of sanders for the type of job, application or sanding project that you want to undertake.

Different surfaces requires different types of sanders, depending on the size of the surface and amount of material that needs to be removed to arrive at the required finish.

In some cases, we might need to remove or sand away a large part of the material, while in other instances, we may just need to remove a thin surface of the material we are sanding. Sometimes we just need to remove paint from a surface by sanding it away.

Whatever the case may be, the type of sander you choose does not only affect the quality of the work, but how fast and efficient you can be when sanding surfaces with it.

Here in this article, I’ve listed the 6 main types of sanders and their applications so you can choose the right one for your project.

Table of Contents

What are the types of wood sanders?

- Orbital sander

- Random orbital sander

- Belt sander

- Spindle sander

- Floor sander

- Straight line sander

Orbital Sanders

The orbital sander is also known as the finish sanders. Orbital sanders are one of the oldest type of sanders used by woodworkers.

You’ll find them in different sizes based on the size of the sheet of sandpaper they use. We have a quarter sheet orbital sander or quarter sheet sander which uses a quarter of a sheet of sandpaper and a half sheet sander which uses half a sheet of sandpaper.

As you can obviously tell, the half sheet sander is larger than the quarter sheet sander because it uses a larger sheet of sandpaper.

Now, when do you need an orbital sander? Orbital sanders are mainly used for fine finishing because they take out very little material. Which also makes it very difficult to damage the surface you’re sanding when using an orbital sander.

The square sanding pad moves vibrates in a small orbit or oval part. That’s why it’s called an orbital sander.

It doesn’t take away a lot of material while doing this. Hence it’s not very effective if you intend to sand away a lot of material. You may need it when you have to apply the final finishing touches to the surface you’re working on.

Also, because it has square edges, you’ll find it very useful when sanding corners of surfaces which you can’t get to with other sanders, like sanding corners of a wooden floor.

The drawback of the orbital sander is that it takes a lot of time to sand with it due to the fact that it removes very little material from the surface. So, if you intend to sand a very large surface, then you might consider checking out other types of sanders.

Random orbital sander

Many a times, people normally confuse an orbital sander with a random orbital sander due to the similarity in their names.

The thing is, even though their names are similar, they’re not the same.

One of the key differences between the two is that while an orbital sander uses square sanding pads which allows you to sand sharp corners with it, a random orbital sander makes use of circular sanding pads.

Also a random orbital sander leaves out better and smoother surfaces than an orbital sander does due to the random motion of the sanding disk.

The circular sanding disks employs two motions when sanding. It rotates in a circular part and also vibrates in orbits at the same time. Hence, the fine particles or grits of the sandpaper don’t pass through the same part twice when sanding with it.

That is why it leaves a much better finish than an orbital sander.

A random orbital sander is also more aggressive, and takes away a lot of material quickly. So, if you’re trying to sand a large surface, you’ll find it very useful.

Though you have to be careful so you don’t dent or damage the surface you’re sanding, as a random orbital sander is much more aggressive and takes out a lot of material quickly.

Unless the one you’re using has variable speed feature for you to adjust the speed to match the job or application you’re using it for.

So, when shopping for a random orbital sander, go for one with a variable speed trigger so you can gain maximum control when using it.

Belt Sander

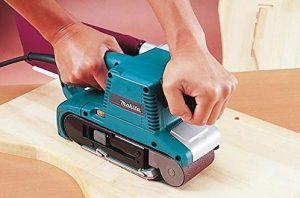

The belt sander is another popular one, though it has acquired a bad reputation because of the damage it causes when not handled properly.

Belt sanders are very aggressive, taking out a lot of material quickly. So, you can’t leave it running on the same spot for too long, else you’re going to have a big dent on that spot or part of the material you’re working on.

They’re very useful if you’re sanding a very large surface and you’re trying to remove a lot of material from the surface.

You just have to make sure that you keep it flat and flush on the surface, and don’t leave it running in one particular spot for too long, else you’ll have a big dent there.

Also, when shopping for a belt sander, keep an eye out for one with variable speed so that you can easily control the speed or rate at which you work with it.

Oscillating Spindle sander

All the previous sanders I mentioned above are all used mainly for sanding flat surfaces. What if you need to sand a curve or groove?

The one you need is an oscillating spindle sander. It’s like a random orbital sander used for sanding curves.

Unlike the previous types mentioned, which are handheld or held with the hand while sanding, the oscillating spindle sander is actually a benchtop model.

It consist of a table top through which a drum or spindle covered with sandpaper or abrasive material protrudes through the top. The spindle rotates in a circular direction and at the same time moves or oscillates vertically in and out of the hole of the table top.

Hence it’s really leaves a nice finish on any material you sand with it. The oscillating and circular motion of the spindle also ensures that the sandpaper does not wear unevenly as a large part of the sandpaper is used during the operation.

Straight line sander

The straight line sander as the name implies sands in a straight line, because the sanding pad moves rapidly to-and-fro in an straight line.

There are straight line sanders with angular sanding pads which conforms to edges and makes it easier to work on right angled edges of wood.

The main benefit of a straight line sander is that it leaves no swirl marks on the material you sand with it, as the sanding pad only moves to and fro in a straight line.

Floor sanders

Last but not the least on this list are floor sanders. As the name implies, it’s mainly used for sanding wooden floors.

It’s usually big and heavy with dust bags and is controlled with two hands around or across the floors you sand with them.

If you’re a home remodeler who’s always tasked with changing or re-purposing hardwood floors, then you should be no stranger to a floor sander.

They’re usually highly priced due to their large and heavy nature. But if you’re a home remodeler and make use of them on a consistent bases, then you should consider owning one if you can.

If you can’t, you can always hire one anytime you have a project that requires it.

Final Thoughts

Like I said earlier, sanding is not the most exciting part of woodworking projects. But with the right type of sander in your tool arsenal, you’ll be able to get it done quickly and efficiently.

Ensure you put safety first when sanding your woodwork. Make use of respirators to keep your lungs clean, amid the huge amount of dust produced during sanding. Also wear appropriate safety glasses to protect your eyes as well from the dust.

Know your sander, use the right one depending on the project you’re tasked with, and get it done efficiently.