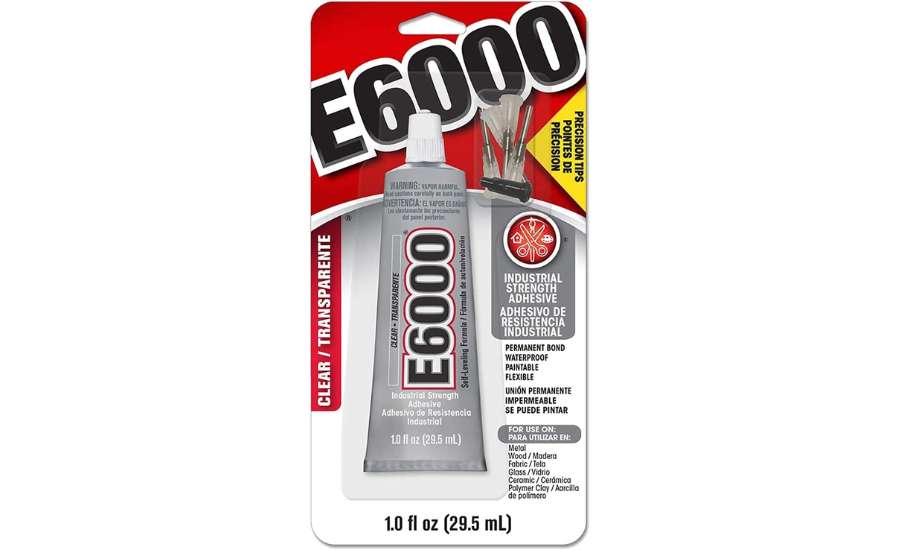

The popular E6000 glue is a versatile industrial-strength adhesive that is used for various bonding and sealing applications such as jewelry making, fabric gluing, woodworking, automotive repairs, sealing and waterproofing.

If you carry out any type of craftwork or DIY projects, then having the E6000 glue in your kit is a must. You can use it to glue just about anything, such as wood, fabric, leather, plastic, ceramics, glass and so much more. It’s great for creating home decor, costume accessories, and other artistic projects.

One particular area where the E6000 shines is in the making of jewelry. You can use it to attach stones, beads, and findings to different materials when making jewelry. And you don’t have to hurry, when placing the items to be glued because it takes between 24 – 48 hrs for it to dry and set completely. So, you have enough time to set stones and perfect your design.

The E6000 glue is made by Electic and it has many characteristics that sets it apart from other types of glues.

When compared to super glue, it produces a more lasting permanent bond because it doesn’t get brittle after drying. It’s flexible and can withstand strong vibrations.

It’s waterproof, it resistant to temperature changes, non-flammable and it’s paintable, among other desirable characteristics that makes it one of the most popular adhesives for crafts and construction.

Application is pretty simple. Just make sure the surfaces you’re gluing together are clean and dry. If possible, roughen up the point of contact a little bit, then apply the E6000 glue directly to the surfaces.

It usually takes up to 24 hours to cure, but it can even take longer, up to 72 hours to achieve max strength.

Before going ahead to buy any e6000 glue however, you need to know that there are different types or variations of the glue worth knowing about. Each of which is best for different types of projects.

So, I’m going to talk about the different types of the e6000 glue so that you know the one to order for your projects.

Table of Contents

Color Variations Of The E6000 Glue

The first thing you need to know about the E6000 adhesive is that it comes in 4 main color variations which are clear/transparent, white, black and gray.

Of all the different color variations, the clear or transparent one is the most common. When it’s dry, you won’t notice any color on the material it’s applied on. I’m sure that’s why it’s the most widely used type.

The white type is used especially for white materials such as ceramics, glass, and white plastics.

On the other hand, the black type is designed for applications where you need a strong bond with a black or dark finish. It’s commonly used in automotive and electronic applications.

The gray variation is used when neither a white or black color variation is needed such as when working with metals.

Nonetheless, you have to note that E6000 can be painted after application to whatever color you desire. That’s why the why the clear variation is the most common one, since you can simply paint it to match surrounding material.

Size Variations

After deciding on the color you need, the next thing you need to consider is how much of the glue you require for your project.

E6000 comes in different sizes, most of which are in tubes. The sizes include: 0.18 fl oz, 0.5 fl oz, 1.0 fl oz, 2.0 fl oz, 3.7 fl oz, 10.2 fl oz (fl oz stands for fluid ounce). It also comes in 1 Gallon, 5 Gallon and 1 Drum.

I don’t know what you would do with a drum of E6000 for, but in case you ever need it, just know that it’s available.

Clear Transparent 3.7 Ounce Tube

The most common variation of the E6000 is the clear and transparent type in a 3.7 ounce tube. If you’ve ever used this stuff, I’m sure this is the one you’re mostly familiar with.

This is the most common one you’ll find in stores, and it’s kind of the all-purpose variation you can use for all kinds of projects.

E6000 Mini Tubes (4)

A little drawback to using the 3.7 ounce tube is that it tends to dry out in the tube after opening it if it’s not sealed properly after use.

That’s why there’s this mini 4 pack 0.18 ounce tube you can buy, so you don’t have to worry about a 3.7 ounce tube going bad if you don’t seal it properly after using it.

You can use one small 0.18 ounce tube at a time while the remaining 3 tubes remain sealed up until you need them.

The smaller tubes also puts out a smaller amount of glue, making it easier to use for smaller projects.

10 Ounce Cartridge

The 10 ounce size affords you more glue to work with, if you’re working on a larger project that will require more of the adhesive.

As with any other type of glue, if you’re not using up everything in one go, then you want to make sure to seal up the remaining glue in the cartridge, else it will dry up, and the remaining one will go to waste.

E6000 Spray Adhesive

Electic Products also produces an E6000 glue variation that can be sprayed on the substrate or material you’re working on.

This can also be used to glue different types of materials, but I think this have a different formulation or make-up, compared to the regular kind, and I think it’s better suited for paper, cardboard, fabric and similar materials.

Electic Products says it can be used for glass and metals, but personally, I think I’d stick to the regular kind of glue for heavy duty materials like that.

One important thing to note about the spray adhesive is that it doesn’t exude toxic smells and fumes as much as the regular E6000.

E6100

The E6100 is an industrial adhesive that is designed especially for overhead applications to prevent any kind of slumping, sagging or dripping of the glue during application.

This affords you maximum control over how and where you apply it without it dripping or slumping off the area where you want it applied.

It also has all the material holding properties of the E6100, and maybe even more. So, you don’t have to worry about it’s holding power. It’s non-flammable, chemical resistant, can be painted after curing, and it’s temperature resistant as well.

E6800

E6800 is a variation of the E6000 designed specifically for outdoor applications. So, if you’re glue up materials that will mostly be used or placed outside, like outdoor furniture or something else, then you should go for E6800.

It’s just the same E6000, but it’s enhanced with UV stabilizers that absorbs UV radiations from the sun and dissipates them as heat, thus preventing glued joints from cracking when exposed to the weather.

High Viscosity vs Low Viscosity E6000

Viscosity simply refers to the resistance of flow of a liquid. In this case, it’s the resistance of flow of the E6000 during application.

There’s a high viscosity E6000 and a low viscosity variation which is the regular type.

The high viscosity variation is thicker and more gel-like in consistency. It doesn’t flow as easily as the low viscosity variation. This makes it less likely to run or drip during application.

This makes it easier to apply, because you have more control over the spread. You’ll also find it useful for filling gaps in the materials you’re gluing.

The regular E6000 (low viscosity) is much thinner and spreads over surfaces easily. It’s more suitable for applications where a very thin adhesive layer is required.

Additionally, because it’s thinner, it possibly has a faster curing time than its highly viscous counterpart.