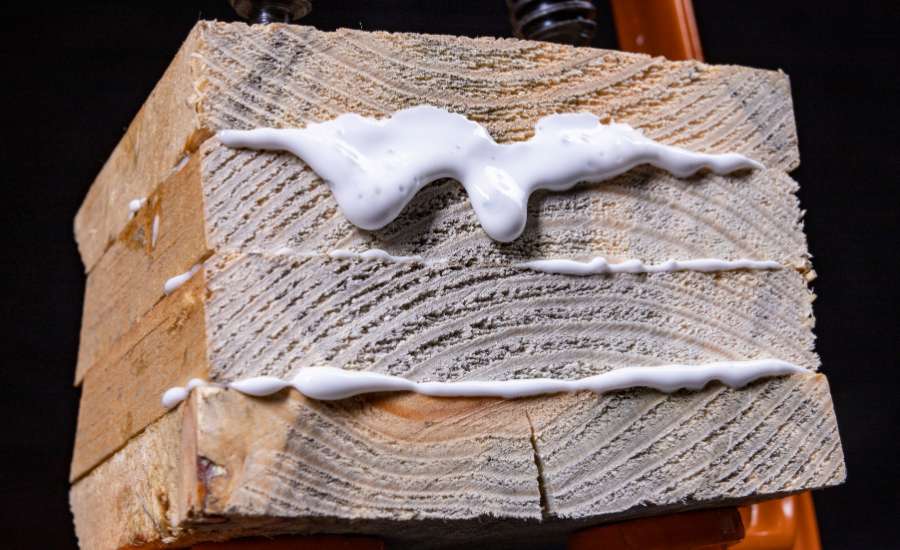

Wood glue is one of the most essential materials needed for carrying out woodworking or carpentry projects. It’s a form of adhesive for bonding or joining two or more pieces of wood together.

Whether it’s furniture making, cabinet or home remodeling, wood glue is a one adhesive you’re going to make use of a lot when carrying out your projects.

Although there are many other ways of joining wood pieces together such as using of nails and screws, the use of glue still creates the strongest and toughest bonds if done properly.

The strong chemical bond created is as a result of the glue soaking into the fibers of the wood, thus creating an inseparable joint.

In fact, the bond created is stronger than the wood itself, such that any attempt to break the joint or separate the wood pieces usually results in the wood breaking instead of the joint.

When carrying out your projects, not every joint or assembling process will require the use of glue. For instance, it’s very unlikely to use glue when carrying out framing projects. On the other hand, when building cabinets or furniture, it’s very necessary to use it.

If you’re reading this article, then you already know that there are different types of wood adhesive. Each one is different from the other, and have different applications.

Some are water resistant and are suitable for outdoor projects, while others are not and are only suitable for indoor projects. Some produce a better chemical bond than others.

Here in this article, I’ve listed the 5 main types of wood glue and what they’re best used for. Before that however, here’s what you should consider when choosing one for your projects.

Table of Contents

How To Choose the Right Wood Glue

Remember, when it comes to adhesives for woodworking purposes, no one size fits all. So, depending on the type of project you’re working on, the type of wood you’re using and the type of joint you’re making, choosing the right wood glue can either be straightforward or quite complicated.

That is why the following few paragraphs are written to help you make the right decision. Choosing the right adhesive can be the difference between an excellent joint and a messy one. So, here’s what you need to consider.

Strength of the Glue

The strength of the bond created after the glue dries up is one of the most important factors to consider before choosing an adhesive.

Some glues created a stronger bond than others. In fact, as already mentioned above, the right adhesive creates a bond so strong that the wood will break or the fibers of the wood will tear off before the bond breaks.

Since some wood glues creates a stronger bond than others, you need to determine how strong you want the joint to be and choose an adhesive able to produce that type of strength.

For instance, CA glue also known as super glue is very hard and rigid, but it’s also very brittle and will break easily with a couple of taps with a mallet or a hammer. This makes it useful for creating temporary bonds.

On the other hand, PVA is rubbery but creates a more lasting and permanent bond between wooden surfaces.

Water Resistance

If the project you’re working on is going to be exposed to the elements like water, then you need your glue to be water resistant. If it’s not, it’s going to fall apart once exposed to water.

For instance, cutting boards are usually exposed to water, because you’re going to be cutting meat, vegetables and other water foods on them. If the glue used to make it is not water resistant, then it will lose its bonding properties as time goes on and break.

The same thing applies to outdoor furniture. They’re going to be exposed to rain, dew and other elements that are going to get the furniture wet. The adhesive used to make this type of furniture should also be resistant to water.

Hide glue can be reversed with steam at any point and thus is not suitable for outdoor projects.

Dry Time / Curing Time

There are 5 different types of wood glue discussed in this article, and each of them takes different time durations to dry and cure.

Dry time refers to how long it takes the wet glue to lose its wetness and attain some strength or hold (at this time, the clamps can go off) while curing time refers to how long it takes for it to attain its full bonding strength.

While some glue such as like CA dries almost instantly, others like PVA takes about an hour to dry but takes up to 24 hours to cure and attain its full bonding strength.

Polyurethane dries and cures faster than PVA, taking just a few hours.

The dry time also known as open time also affects how these adhesives are used. For instance, if you need some time to adjust a joint after applying the adhesive, then CA will never be advisable because it dries up almost instantly.

On the other hand, after applying PVA, you still have some time to adjust the joint, align the members carefully and adjust your clamps before it dries and holds up.

Viscosity / Thickness – Gap Filling

The viscosity, density or thickness of the glue also affects the types of projects it can be used for.

In certain situations, it’s possible there might be small gaps or irregularities between the pieces of wood you’re trying to join together. Gap-filling or highly viscous glues can help bridge these gaps and create a stronger bond between the surfaces, even when the joint isn’t a perfect match.

However, while gap-filling properties are beneficial, they don’t replace the need for proper joint preparation and accurate woodworking techniques. It’s always a good practice to strive for a well-fitted joints whenever possible. Nonetheless, when the situation you have at hand is less than ideal, a glue with gap-filling properties can help you achieve a strong and reliable bond.

For small repairs like little cracks and hairline splitting in wood, CA or super glue is excellent as it flows easily and dries up quickly.

PVA is a bit light and runny too but it’s much thicker than CA and soaks up easily into wood fibers, providing a good chemical bonding between members of a joint.

Epoxies are the thickest and are ideal for filling up large cracks. Polyurethane such as Gorilla glue is also thicker than PVA and even expands while drying, thus requires more clamping force to keep it in place.

Color / Stain Absorption

Some adhesives like PVA and Epoxies doesn’t absorb stain and they reveal a different color after drying up. So, if there’s any left on the wood surface, it will show even after the project has been stained.

Hide glue on the other hard rarely shows after application and doesn’t affect staining in any way.

Shelf Life

Shelf like refers to how long an adhesive can be stored away without being used and still retain it’s bonding capabilities.

This will affect how much of that adhesive you can buy based on how much of it is being used on a daily basis. If stored properly, CA adhesives can stay up to 10 years and still retain their bonding capabilities. PVA, Hide and polyurethane however will not last more than one year and still retain their bonding properties.

With that said, the following are the different types of wood glue you can use for your projects.

Temperature Resistance

Certain types of glues like hide glue can lose their bonding strength due to increase or decrease in temperature. That’s why it’s important to consider how increase or decrease in temperature affects any type of glue you choose to use.

A situation where you must consider this is when building outdoor furniture with wood. Imagine building a patio table with wood glue that loses or gains more bonding strength due to increase or decrease in temperature. During hot summer days, the table is exposed to intense sunlight and high temperatures, which can cause the bond to weaken, and cause the joints in the table to loosen or fail totally.

Also, a kitchen cabinet positioned near an oven or stove, made with glue that’s not temperature resistant will fall apart as you continue to use it, because the surrounding temperature can become elevated during cooking.

On the other hand, if the glue is temperature-resistant, the bond will remains strong and reliable despite the changing temperatures in the kitchen.

Reversibility

Like I mentioned above, some glues react to temperature changes and can either lose or increase their bonding strength due to increase or decrease in temperature.

That is why, considering the reversibility of wood glue is important when carrying out projects, especially in situations where the joint might need to be disassembled or repaired in the future without causing irreparable damage to the wood pieces.

Hide glue has been used for a very long time to make furniture. That’s why when you happen to get your hands on certain antique furniture, you’ll find out that most of them are quite easy to restore because they wear made with hide glue which comes apart quite easily when the joint is steamed.

The reversibility of certain glues can also come in very useful when when making wooden prototypes for a project. During the prototype phase of a project, adjustments and modifications are common. Using reversible glue allows for easy changes and adaptations without needing to start from scratch each time.

While the bonding characteristics of reversible glue still leaves more to be desired when compared to their permanent counterparts, their benefit in allowing for future alterations or repairs can often outweigh this trade-off.

Types of Wood Glue

Here are the 5 main types of wood glue you should know.

PVA (Polyvinyl Acetate) Wood Glue

Polyvinyl acetate also known as PVA glue is the most common wood glue around today. It’s so common, I’m pretty sure you already have it in your house or workshop.

It comes in different forms and varieties. One of the most common ones being the yellow aliphatic resin carpenters glue which is a true staple of the woodshop and has been available since the beginning of the 20th century.

Talking about yellow glues, Titebond is the leading brand in the market, and they have different types you can choose from depending on the project you’re working on.

There’s Titebond Original, Titebond II, and Titebond III. They’re all the same yellow glue made by the same manufacturer (Titebond), but they differ in terms of resistance to water, open time and pricing.

Titebond Original is not water resistant. That’s why it’s best you use it for interior projects only. Titebond II is water resistant, hence can be used for making projects that will be exposed to water such as cutting boards and outdoor furniture.

Titebnd III is water proof or more water resistant than titebond II, and thus can be used for projects that will be submerged in water or projects that frequently come in contact with water.

In terms of open time, Titebond III has twice the open time of Titebond II and Titebond Original. So, if you need more time to set and adjust the joint after spreading glue on the different pieces, then you need to go for Titebond III.

Another popular PVA is the Elmer’s white glue. It’s non-toxic, cleans up easily with water and produces a strong joint once it’s cured.

The only downside about PVA is that it does not absorb stain the way wood does, so any excess glue left on the wood surface will still be visible after the wood is stained, if it’s not wiped off or sanded off before staining.

Polyurethane Glue

If you’ve heard of or made use of Gorilla glue, then you’ve used polyurethane as well. Gorilla glue is just the trade name for it.

Polyurethane produces a very strong bond and can be used to join different materials such as metal, ceramics, stone, fabric and wood.

Hence they’re ideal in places where the strength of the bond is of utmost importance such as when making woodworking jigs.

You have to be careful though when using it on final assembly projects because it expands as it sets and can quickly form a mess on your project.

So, it’s best to use it only on projects you still have to sand or plane down to get the final finish.

Polyurethane is also water resistant, thus it’s suitable for outdoor furniture projects that will be affected by rain/weather.

Related: 40 Modern Woodworking Tools For Every Woodworker Should Have

Hide Glue

One of the oldest form of adhesive you can use today is hide glue. As the name implies, it’s made from animal hide.

Traditionally, it comes in the form of dry flakes or pellets which is then melted down using double boilers and applied while it’s still warm.

Currently though, there are liquid forms manufactured by companies like Titebond and Old Brown, although the traditional hide glue produces the strongest bonds as it contains no additives that neutralizes the strength of the bond created.

Hide glue has some desirable properties which makes it the adhesive of choice when making antic furniture or for projects you intend to take apart in the future for repairs.

By simply warming any hide glue joint, the glue will loosen up and you can take the furniture apart for repairs. Hide glue can also be stained unlike other wood adhesives and it’s non-toxic as well.

Epoxy

Epoxy is a two-part glue. One is resin, the other is a hardener. When mixed together, they harden and form strong glue which is majorly used for filling gaps in wood or repairing a damaged wood.

It’s resistant to different elements such as water, heat and ultraviolet light. It also adheres to a wide range of materials including plastic and metal.

However, even though it produces a very strong bond when used in the right places, epoxy glue not suitable for gluing very tight fitting joints.

CA Glue

We all know it as Superglue or Crazy glue which are actually trade names for it. The generic name is Cyanoacrylate or CA.

Although it can be used to join almost anything, it’s not meant for large glue ups. It’s best for small repair jobs such as gluing chipped wood or cracked wood.

CA glue dries up quickly and it’s available both in liquid and gel form.

Related: Wood Stain Tips Every Woodworker Should Know

Conclusion

Before you go, here are a few things you need to take note of when buying wood glue for your next woodworking project.

First, the material you’re gluing up should decide the type of glue you buy. You shouldn’t buy a one just because it’s the strongest.

For instance, Polyurethane or Gorilla glue as it is commonly known is very strong, but it’s not recommended for finished or final assembly projects as it can form a mess on your finished project.

Epoxy is also very strong, but it’s best for filling up large cracks or loose joints instead of tight fitting ones.

So, the material you’re trying to join should determine the adhesive you choose.

Secondly, buy just the right amount of glue you need. Don’t buy in bulk. Buy in small containers so that it remains fresh.

If you have some leftover, read the labels so that you know how to store the it. Some adhesives such as hide glue lasts longer when they’re refrigerated.

Finally, date your glue bottles immediately you open the seal so that you know how fresh they are.

The older they get after you open them, the more strength they lose. So, always date them to make sure you’re not using it when it has lost almost all its holding power.

With the information above, we hope you make the right choice the next time you’re buying glue for a woodworking project.

thanks for the tips. very helpful.

You’re welcome. I’m glad you found it helpful.