A benchtop thickness planer is simply a portable machine you can use to plane or mill rough boards in the workshop or on the jobsite.

It can be used along with a jointer to ensure the boards you work with are consistent in thickness. That’s why it is undoubtedly one of the most important tools required woodworking projects.

It’s also called a surface planer because you can use it to remove imperfections such as knots, warps, and mill marks from the surface of your lumber pieces, leaving you with a smooth and uniform finish. This is especially important if you’re working on projects that require precise fitting or require a consistent surface for staining or finishing.

Our Top Picks

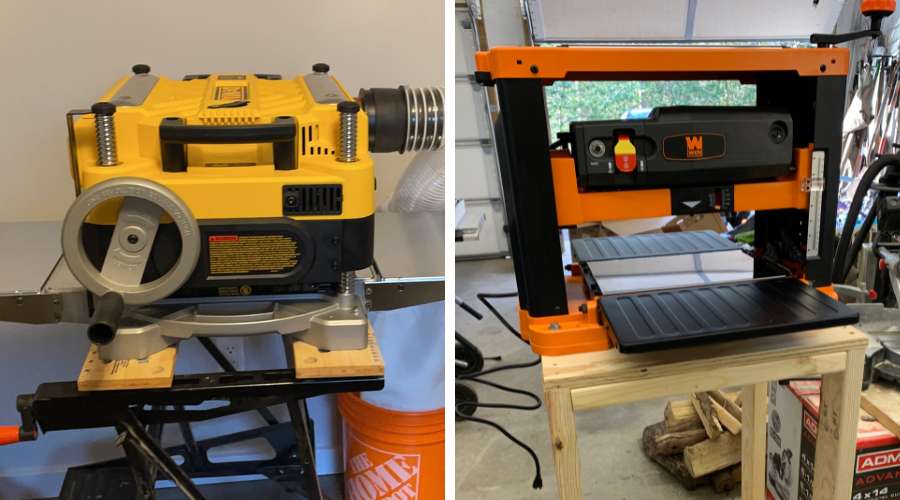

Shop Fox W1877 | Dewalt DW735X | WEN PL1326 |

|  |  |

|

|

|

Table of Contents

Why Get A Benchtop Thickness Planer

Generally, thickness planers come in the form of massive, heavy-duty industrial floor machinery, which are pretty expensive, especially for the average hobbyist and DIYer.

Hence the need for portable types commonly known as benchtop planers.

A benchtop planer works just like the larger floor / industrial or cabinet planer, only at a lower capacity.

For example, with an industrial or cabinet unit, you can plane lumber as wide as 20 inches and above, whereas benchtop planers can only handle a maximum of 13-inch boards.

Hence, the portability comes at a price that can be overlooked because having a heavy-duty planing machine might be too expensive and not ideal, especially for a simple hobbyist or DIYer who uses it sparingly.

On the other hand, the portability means you don’t have to own a big workshop to get one. Your home garage is even big enough.

Also, contractors can use it on job sites because it’s portable and can be moved easily by one person, unlike big floor models designed to be used in the workshop.

There are many brands and manufacturers of thickness planers today, each with unique features. That’s why choosing the right one can be complicated or confusing, especially if it’s your first.

However, I’ve narrowed down the options to 10 of the best units, so you can choose the one that’s right for your projects.

If you’re looking for something other than a portable or benchtop planer, you can check out this guide here for heavy-duty industrial units.

1. Dewalt DW735X Benchtop Thickness Planer Review- Best Pick

The Dewalt DW735X is one of the only portable thickness planers with a 13-inch width capacity, allowing you to plane wider boards than most other portable planers.

That alone is one single reason why most people go for it. It’s for the wider width capacity.

One more thing you’ll notice when you get the DW735X is that the cast aluminum base is almost twice as thick as the base of other units. It has a 19-3/4 inch base compared to the 10-inch base found in other portable units. This makes it more rigid and stable during use.

Another important feature that stands out in the DW735X is the 2-speed gearbox it has. This allows the user to change feed speed from 96 cuts per inch (CPI) to 179 CPI. This will enable you to either optimize the amount of material removed using a slower speed or remove less material while improving the surface finish using the faster speed setting.

The only upgrade I’d like to see on the DW735X is a spiral/helical cutterhead instead of the standard straight knife cutterhead.

That will reduce the noise produced and improve the finish quality. Although, unlike most other benchtop planers with a 2-knife cutterhead, the Dewalt DW735X features a 3-knife cutterhead. This also improves the surface finish on the wood you’re planing, and also makes the knives last longer than a standard 2-knife cutterhead.

One more thing you get with the DW735X is infeed and outfeed tables to support your workpiece and reduce snipe.

At the heart of the setup is a powerful 15-amp motor, running at a speed of 20,000 rpm and spinning the cutterhead at 10,000 rpm.

The fan-assisted dust ejection feature of the DW735X also puts it one step above similar units.

Related: Which Dewalt Planer Is The Best – DW735X vs DW735 vs DW734

What we like about it

Where it can be improved

2. Wen PL1337 Benchtop Thickness Planer – Spiral Cutterhead

For so many years, the Dewalt DW735X had no close rival when talking about portable benchtop thickness planers due to several distinct features it possesses.

Now however, many other brands are offering the same features which makes the DW735X stand out from the competition such as it’s 13 inch width capacity, and it’s dual speed operation.

One of such brand offering is the WEN PL1337. The WEN PL1337 not only features a 13 inch width capacity and a dual speed gearbox, but it also features a spiral cutterhead which leaves a much smoother finish on boards planed with it, and also enables the machine to work much quieter.

It comes equipped with a 15 amp motor with a rotational speed of 10,000 RPM, generating up to 1354 cuts per minute. The PL1337 will allow you to plane boards up to 6 inches in thickness and 13 inches in width, which is the maximum for most portable thickness planers.

The machine have many other features and accessories such as an onboard material removal gauge, a depth stop, infeed and outfeed tables, and a suitable dust port to expell the dust produced during use.

Overall, I’d say the WEN PL1337 is surely one of the best benchtop thickness planers out there, and I’d recommend it in a heartbeat to anyone looking for a portable machine like this for use in the workshop or on the jobsite.

What we like about it

Where it can be improved

Related: The Best Jointer Planer Combo Machines for Planing Rough Lumber

3. Shop Fox W1877 Benchtop Thickness Planer

The first thing you’ll notice about this Shop Fox W1877 is that it’s pretty expensive compared to the other portable thickness planers reviewed in this article.

Upon further examination, you’ll also notice it’s one of the most well-built planers out there, with every feature needed to turn rough boards into smooth ones ready for fine woodworking projects.

For one thing, it comes with a very powerful 2 HP 15 Amps motor, which allows it to chew through any type of wood you throw at it. That means you can also plane at its maximum cut depth of 1/8th of an inch without bugging the machine down.

The Shop Fox W1877 comes equipped with a spiral-style cutterhead with 26 indexable carbide inserts, something you’ll also not find in most portable planers. This enables you to plane boards with a better surface finish, resulting in a much quieter machine even when under load.

It has a maximum width capacity of 13 inches, accepts a maximum board thickness of 6 inches, and has a maximum cut depth of 1/8 inch. The cutterhead spins at a maximum speed of 10,000 RPM, with a feed rate of 26 feet per minute.

For dust collection, the W1877 features a large 4-inch dust port to connect it to your workshop dust collection system. It also includes a 2-inch and 1/2-inch adapter for connecting it to suitable shop vacs.

All in all, I can say the Shop Fox W1877 is one of the best options to consider when shopping for a portable thickness planer unit, especially if the price is not a deciding factor. Quality-wise, it’s well built with very good in-feed and out-feed tables for material support.

Depth adjustment is also effortless with a hand wheel right at the side of the unit and a marked thickness scale to read settings.

What we like about it

Where it can be improved

Related: Jointer or Planer – Which Tool Should You Get First

4. Rikon 25-135H Portable Thickness Planer

The Rikon 25-135H portable thickness planer is a bit pricey compared to the other units in this list, but it also come with premium features you’ll not find in some of the rest.

One of its most notable features is the helical-style cutter head it comes with. It’s a 6 row helical-style cutter head with 26 high speed steel (HSS) precision sharpened inserts.

Each of the inserts are sharpened on two edges so you can rotate them if one edge gets blunt. To rotate it, just loosen the screw that holds the knife, rotate it to the new edge, retighten it and you’ve got a new edge to work with.

One of the advantages of the helical-style cutter head on this Rikon 25-135H is that it shears through the wood at an angle, thus producing very clean and smooth cuts. So smooth that it requires very little sanding. The shearing action also reduces the noise, which makes it less noisy than thickness planers with a straight knife cutter.

With a depth capacity of 6 inches and a width capacity of 13 inch width capacity, you can really plane wider boards with this machine when compared to other portable planers with 12 inch or 12.5 inch width.

The Rikon 25-135H comes equipped with a 15 amp 115 volts motor with a no load speed of 22000 RPM. This spins the cutter head at a speed of 10,000 RPM.

It has a 2-speed feed rate, with a slower speed which provides more torque for maximum stock removal, and a faster feed rate for finishing the surface.

There’re in-feed and out-feed tables for material support when feeding boards in and out of the machine.

It also features a 4-post threaded support for the cutter-head to improve the stability and accuracy of the machine when making cuts. At the top of the machine is the height adjustment crank to easily set the depth of cut.

It also comes equipped with a turret depth stop to make repeat cuts and avoid removing too much material from your stock.

The whole frame is made purely out of steel for durability, and for it to stay rigid and wobble-free during use.

All in all, although this Rikon is quite expensive compared to other portable benchtop planers, it’s got all the necessary features you need to carry out your projects with great precision.

What we like about it

Where it can be improved

Related: The 5 Best Portable Benchtop Jointers for Woodworking Projects

5. Dewalt DW734 Benchtop Thickness Planer

The Dewalt DW734 benchtop planer features a 3-knife cutterhead just like the DW735X. The 3 knives are double-edged, which means you can reverse them after one edge gets dull or blunt.

Spinning the cutterhead is a powerful 15 amp motor that produces a maximum speed of 20,000 RPM, so the user can work on any stock, whether it’s hardwood like oak or softwood like pine wood.

The motor spins the cutter head at 10,000 rpm, producing 96 cuts per inch to ensure the finest finish on the stock.

At the top of the machine is a depth adjustment knob that allows you to raise or lower the cutterhead for easy depth control.

It also has a turret depth stop so that you can make repeat cuts easily and avoid over-planing your lumber pieces.

Large infeed and outfeed tables provide enough space to support the stock and reduce sniping at the ends of the boards.

It also comes equipped with an easy-to-read thickness scale so the user can know how much material will be removed on every pass through the machine.

A large and easily accessible paddle switch ensures you can turn it off whenever needed.

What we like about it

Where it can be improved

Related: The 10 Best Electric Hand Planers

6. Makita 2012NB Benchtop Thickness Planer

The Makita 2012NB thickness planer comes equipped with a 2 knife cutterhead which has a no-load speed of 8500 RPM. Pass your stock through this, and you’ll likely be blown away by the results.

The cutter head blades are double-edged, thus they can be reversed when one edge gets dull so you don’t have to buy replacements right away.

It has a width capacity of 12 inches, a depth capacity of 6 -3/32 inches and a maximum cut depth of 1/8 inches.

A very good feature I always want on any planer is the depth stop which this Makita also has. This ensures you don’t over plane your stock past a certain depth, say 5 inches. So, you can set the depth stop at 5 inches, and you won’t be able to crank the cutterhead less than 5 inches.

It comes equipped with large infeed and outfeed tables to fully support the stock and to prevent sniping at the ends

Makita equipped this with an interna-lok automated head clamp that locks the cutterhead in place to limit the movement that causes snipe and improve the performance of the machine.

In terms of design, the Makita 2012NB is compact and lightweight for easy transportation to the jobsite. The lighter weight is usually not a problem because it can be bolted to a workbench to prevent movement and vibration during use.

A powerful 15 amp motor keeps the cutter head running.

What we like about it

Where it can be improved

7. Mophorn Thickness Planer

This is the first tool from Mophorn I’ve had the opportunity to review, but even though I had my doubts prior to this review, I can say now that the performance and quality exceeded my expectations.

The Mophorn thickness planers is one of the few units with an already-made stand that allows you to use the machine conveniently at the right height.

Apart from that, the stand also makes it more rigid, preventing it from wobbling during use. The stand can be detached from the planer unit, so you don’t have to worry about carrying both simultaneously if you have to move or transport it.

The width capacity is just 12.5 inches, while the depth capacity is 6 inches. Still, you can carry out a lot of projects with it, especially if you’re a weekend warrior or contractor who needs a portable machine for jobsite use.

For power, the Mophorn comes equipped with a 1500 Watts motor which turns the cutter head and roller assembly, allowing you to feed in boards at a rate of 315 inches per minute.

It has a maximum cutting depth of 0.1 inches, with the 2-blade cutterhead spinning at 9000 RPM, thus helping you get a quality and smooth finish on your boards.

For protection against electric current overload, the Mophorn portable thickness planer comes equipped with a power-off electromagnetic switch that turns off the machine in such cases.

The crank at the top allows you to make depth adjustments easily. In-feed and out-feed tables provide additional material support and prevent snipe at the ends of your lumber pieces.

Overall, I’d say this is a very capable and durable machine you can use to plane and dimension boards both in the workshop and on the jobsite.

What we like about it

Where it can be improved

8. Delta Power Tools 22-555

The 22-555 model is not the most recent model of the Delta Power Tools thickness planer, but it’s certainly the most popular.

Its 4 column design provides rock-solid support and stability during use.

The cutterhead on this one is a 2-knife cutterhead but the boards planed with it also came out very smooth.

The knives are dual-edged, which means you can reverse them after one edge gets dull, so you don’t have to buy replacements too soon.

Changing the knife is very easy and fast because there’s no need for the use of knife alignment jigs on this one.

The Delta Power Tools 22-555 benchtop planer features adjustable in-feed and out-feed tables for extra material support and to prevent sniping.

It comes equipped with a 15 amp motor, so you can plane both hard and softwood with it.

The cutterhead delivers up to 18,800 cuts per inch at a feed rate of 28 feet per minute, producing the smoothest cuts even on very hard lumber pieces.

It has a width capacity of 13 inches, a 6-inch depth capacity, and a maximum cut depth of 3/32 inches.

A reversible dust port makes dust collection a breeze because you can hook your shop vacuum to either side of the machine.

What we like about it

Where it can be improved

9. Craftsman CMEW320

Like the other machines reviewed, this Craftsman CMEW320 benchtop planer comes with a 15 amp motor for maximum power and speed.

The motor spins the cutter head at 8,000 revolutions per minute, making 16,000 cuts per minute on the stock, ensuring a very smooth surface is produced on the material.

The 2-knife quick-change solid steel cutter head comes equipped with double-edged knives made of high-carbon steel. These won’t get dull quickly, and you can even reverse them when they finally do.

Included is an easy-to-read depth gauge to make easy depth adjustments and a big paddle switch so you can switch off the machine conveniently.

It also comes with large in-feed and out-feed tables for good material support, with a depth adjustment knob positioned right at the top to easily access it.

A vacuum port at the back provides easy access to connect a shop vac to eliminate chips and sawdust produced.

Also featured is a Poly-V cutter head drive for maximum transmission of power from the motor.

What we like about it

Where it can be improved

How To Choose A Benchtop Thickness Planer

Choosing a portable benchtop thickness planer for your project can be quite complicated if you haven’t used one before. But with the following guide, you’ll know what’s essential and what’s not.

Here’s what you must consider.

Width Capacity

The width capacity of a thickness planer is the maximum size of boards in width it can accommodate. One with a width capacity of 13 inches can plane boards not more than 13 inches in width, and that with a width capacity of 12-1/2 inches can plane boards not more than 12-1/2 inches in width.

When making your choice, the higher the width capacity is, the better it is because you can plane wider boards with it without trying to downsize the boards.

Here are the width capacities of the 10 reviewed in this article.

As you can see from above, the width capacities of portable thickness planers usually range between 12 and 13 inches. Personally, for small DIY / jobsite projects, you can’t go wrong choosing either 12 or 13 inches because the additional 1 inch doesn’t really matter much.

Nevertheless, the additional 1 inch does provide a little advantage of working with slightly wider boards.

Of course, if you need something with a larger width capacity than 13 inches, you can always go for a stand-alone cabinet unit with the capacity to plane boards as wide as 20 inches and above.

Type of Cutter Head

One of the most important features to look out for when choosing a thickness planer is the type of cutter head it has.

That’s because the quality of the one you choose is primarily determined by the type of cutter head it comes with. The cutterhead affects the following:

- It affects the smoothness or surface finish of the boards you cut with it.

- It affects the noise produced by the planer during operation and

- it determines how much you’ll spend to replace it.

With that said, there are two main types of cutterheads available in these machines.

Which are:

- Straight knife cutterhead and

- Helical or Spiral cutter head

The straight knife cutterhead is the most common one you’ll find in most benchtop thickness planers. It usually consists of 2 to 4 straight knives arranged around the cutterhead.

They’re usually made with high-speed steel, and thus they’re cheaper compared to helical cutterheads which are made with carbide steel.

They get blunt easily because they’re not as hard as carbide, but it’s cheaper to replace them, or you can sharpen or reverse the direction of the knives if they’re reversible.

Helical cutter heads, on the other hand, do not feature long straight knives that run the length of the cutter head. Instead, they feature multiple rows of small square-shaped cutters called inserts configured in a helical or spiral orientation as shown below.

Although some woodworkers prefer thickness planers with straight knife cutter heads over the helical style, the helical or spiral style cutterhead has few noteworthy advantages over the straight knife cutter head.

One of the main advantages is the ease of replacing the carbide inserts on the helical cutterhead if any one of them gets nicked or damaged.

When you mistakenly run a nail-embedded wood through your planer, just 1 or 2 carbide inserts might get damaged if it’s a helical style cutter head, and they’re very easy to replace.

In fact, you don’t have to replace the carbide inserts the first time they get nicked; you only have to loosen the nicked inserts and rotate them 90 degrees to reveal a new sharp edge, and it’s as good as new.

Each insert can be rotated 3 times before it’s finally replaced because all four edges are sharpened and can be used for planing.

On the other hand, replacing the knives of a straight knife cutterhead is difficult and time-consuming. First, you have to loosen and remove the damaged knife or blade, then you have to replace and re-align the new blade with the rest of the blades in the cutterhead.

Another important advantage of having a thickness planer with a helical cutter is that it reduces the noise produced by the machine.

Byrd produces a helical cutter head they call the Shelix. On the shelix, the carbide inserts on the cutter head are inclined at an angle to the feed direction so that it produces a shearing action as they slice through the wood without causing much noise.

Straight knives on the other hand cuts through the wood directly at 90 degrees, which scoops the wood and produces a louder sound.

Dust collection is also better with a helical style unit. The small cutters produce little wood chips which your dust collector can easily pickup without clogging the hose or your ductwork.

On the other hand, the straight knife cutterhead produces long chips which are more difficult to extract by any dust collection system.

Cut quality and lower cost of maintenance are two more advantages of a helical-style unit over a straight knife unit.

On the downside, machines equipped with helical cutter heads have more initial costs than those with straight knife cutter heads.

Motor

The benchtop thickness planer you choose should have a good-quality motor spinning the cutterhead and working the infield and outfield rollers.

Having a good quality and powerful motor will ensure you can plane any wood with it, whether it’s hardwood like oak or softwood like pine.

Most benchtop planers come equipped with 15 amp motors turning the cutterhead at speeds ranging from 8000 rpm to 10000 rpm.

The faster the RPM, the smoother the finish it can produce. That’s because a faster cutterhead means more cuts are taking place per inch of the wood as it’s fed through the machine.

Feeding your wood stock into a less powerful planer also takes longer due to slower feed rates.

Part Replacement

A benchtop planer is like any other machine. It will not stay the same forever. Some parts will need replacement after some time. So, you need to make sure the one you choose has parts that can easily be found in your local dealer’s shop or ordered online.

Talking about part replacement, it’s also good to check the warranty. Ensure you can return it if it falls apart too soon.

Good Cast Iron Base

Planing lumber involves the movement of different powerful machine parts and the cutting of lumber in these parts, which results in vibration. Having a good cast iron base helps keep the machine stable as you work with it.

Ease Of Making Depth Adjustment

Depth adjustment should be a breeze in any benchtop thickness planer you choose. There should be precise gauges, visible linear scales, and clear directions on how to use and adjust them, so you can plane or trim your boards to the particular dimension you want.

Snipe Handling

Snipe is one nasty wood defect that occurs when feeding boards in and out of a planer as a result of the weight of the board pulling downwards at the free ends, thereby pushing the opposite end into the cutterhead, which creates a dip at the ends of the board.

Sadly, snipe is something that cannot be eliminated totally without providing enough manual support for the material. However, it can be reduced to a great extent if the thickness planer you choose have a few features built in like sturdy outfield tables and mechanisms that locks down the cutterhead from moving during use.

The Dewalt DW734 features a black bar at the top, which, when pulled down, engages an automatic carriage lock that locks down the cutterhead and roller assembly, thereby limiting any upward or downward movement that may cause sniping.

While the Dewalt DW735X’s means of mitigating snipe is automatic, you don’t need to pull down anything to lock down the cutterhead and roller assembly. It locks down by itself as soon as you finish adjusting the depth. This drastically reduces snipe and makes the planing process easier and more accurate.

The Makita 2012NB features an interna-lok head clamp which also helps to lock the cutterhead and roller assembly in place to reduce snipe.

In summary, check out and make sure that the planer machine you choose has a few features that help it handle snipes properly. However, to effectively reduce snipe totally, you also have to support your workpiece manually with your hand while feeding it into the machine, and also support it while it’s out-feeding on the other side.

Also, ensure that the one you choose comes with in-feed and out-feed tables because they go a long way to support the wood, thereby reducing snipe.

Dust Collection

Many woodworking tools create a lot of sawdust, and a benchtop wood planer is an excellent example. It can turn your whole workshop into a huge mess without a proper way to direct, funnel, and collect the dust created.

That is why you must ensure the one you choose has a good dust/chip collection port to expel the dust produced by the machine in a controlled manner.

Some thickness planers like the Dewalt DW735X and the WEN 6552T come with a fan-assisted dust collection port that helps to blow chips and dust out of the machine.

Precision

What is the surface of the finished board like? Is it smooth, or does it still need much work with a sander? How accurate is the thickness or depth scale?

The one you should choose should be able to produce a smooth surface on any wood so that the resulting stock will require minimal sanding if necessary.

Price

Price is another factor that may affect your decision. Some units are obviously more expensive than other ones which can be caused by several factors, such as superior build materials, branding, extra features and more. However, you should always go for what your budget allows.

How frequent you intend to use the planer should also determine the type you get. If you’re a professional woodworker who’ll be using it on a regular basis, it’s totally worth it to go for the best with the best features and build quality.

On the other hand, if you’re a weekend woodworker who’ll be using it sparingly, then it’s okay to get a budget unit, since you’ll not be working it that hard.

At the end of the day, a better tool may have more initial cost, but it will afford you more comfort, performance, and durability, which you may not have with a cheaper one.

Conclusion

No planer will be 100 percent in every angle. There’ll always be some features it has and others it lacks.

It all comes down to what you’re willing to sacrifice for another. We hope this guide helps you choose the right portable thickness planer that will makes your job as a woodworker, DIYer, or hobbyist as easy and efficient as possible.