A track saw may look like a fancy circular saw, but it has more features that makes it far better than a regular circular saw. It’s designed for accurately breaking down and trimming large materials like sheet goods, table tops, and doors.

A track saw cuts much more accurately because it comes with a guide rail with tracks which provides a stable and straight cutting path, ensuring precise and splinter-free cuts.

The guide rail ensures straight and precise cuts, eliminating the need for additional clamping or measuring. It also acts as a reference point, allowing for repeatable accuracy even with large workpieces and sheet goods that needs to be ripped down to smaller sizes.

A track saw is also called a plunge-cut saw because you can lay it flat directly on the material and adjust the blade to protrude down, plunging into the material to make the cut—something you can’t do with a traditional circular saw.

You may already have a table saw, a circular saw or even a panel saw and are wondering why you should get a track saw. You should get it because it provides an easier and more accurate way to make long rip cuts.

Unlike using a table saw, you don’t have to bring the material you want to cut to the saw; you can bring the saw to the material.

That means you can rip-cut and break down huge boards, which are usually too large to cut or handle on a table saw.

Table of Contents

What To Consider When Choosing A Track Saw

The most important factors to consider when choosing a track saw are the amount of power it has, the ease of maneuvering the tracks, dust collection, whether it’s cordless or corded, and price.

Now, let’s talk about each of these factors in detail.

Power

Sometimes you can only tell how powerful a tool is once you use it yourself or get feedback or reviews from people who already own it.

Most of the time, for a new tool, we rely on the amp ratings, the speed, and the amount of horsepower the motor has.

Even though these ratings don’t tell the whole story, it’s important that you consider them. All things being equal, a 15 amp rated track saw will be more powerful than one with a 10 amp motor, and it will not bog down under load.

When making your choice, try not to dismiss cordless units as underpowered. Our findings show that the cordless Festool track saws are even more powerful than their corded counterparts, which sounds and feels weird, but that’s just the reality of things.

Cordless tools are no longer inferior in power to corded ones as they used to be back in the day. The batteries last longer, the saws are powerful, and they’re even more portable to use on the job site.

Ease of Maneuvering the Tracks

The primary thing that differentiates track saws from standard circular saws is the guide rails they slide on. This makes the guide rails or tracks important to the saw.

These tracks should be easy to maneuver around your workpiece without any issues. It should be light enough to carry but strong enough to withstand abuse on the job.

Good tracks don’t require clamps to keep them in place on the workpiece. Instead, thin non-stick strips are lined underneath the tracks that keep it from shifting when making cuts. With this, there’s no time spent setting up the saw before making your cut.

Some of the ones we reviewed here come with tracks to use right away, while others are just the bare tool. You have to buy the track separately.

Some tracks from brands like Makita, Festool, Dewalt, and Bosch are interchangeable. That means if you already have a Festool track saw with its guide rails and want to buy a Makita track saw only without the guide rails, it will match your Festool guide rails. So you don’t need another set of guide rails for it.

Dust Collection

Dust collection is very important when working with track saws, especially when you’re using it inside the shop.

Track saws are designed to rip long lengths of sheet goods, that’s why they produce lots of sawdust. Most of the new models you’ll find today have a dust port right at the back of the saw for expelling dust as you make cuts with it. Some older models don’t have this feature, which means you can’t hook a shop vac or dust collection hose to the unit if you want to.

So, try to consider this when making your choice.

Cost

Cost undoubtedly influences your decision if you’re trying to buy a track saw because the prices of the track saws reviewed here range from less than $100 to nearly $1000.

As a professional woodworker, it’s crucial you get a high-quality one because it’s a tool you will use daily. A low-quality unit may not be able to keep up with this frequency of use and may not give you the kind of performance you need.

On the other hand, buying a cheaper one is fine if you’re a simple DIYer who might not use it regularly.

With that said, here is our list of the 6 best track saws you can use for your woodworking projects.

1. Makita SP6000J1 Plunge Cut/Track Saw Kit

If you’re talking about the best plunge-cut track saws, you can’t complete the discussion without mentioning Makita.

Theirs is one of the best models you can go for. The Makita SP6000J1 plunge-cut track saw kit offers you a true cutting system you can rely on for all your plunge cuts and rip cuts both on and off the jobsite.

It features a 6-1/2 inch blade powered by a 12 amp motor to produce smooth splinter-free mirror finishes on your material of choice.

It also comes equipped with a 55 inch guide rail which the blade glides along affording you the capacity to make long rip cuts with the greatest accuracy.

The body is made with magnesium components to decrease the weight and make it easier to handle for long periods of time.

Controlling the speed is done electronically allowing the blade to maintain a constant speed under load to produce splinter-free results.

Apart from that, the Makita SP6000J1 comes equipped with a variable speed control dial you can use to vary the speed from 2000 to 5200 RPM.

This ensures you can adjust the speed of the blade to suit different types of materials.

You can make bevel cuts from -1 degree to 48 degrees, with positive stops at 22.5 and 45 degrees respectively.

Additionally, as a plunge-cut saw, the saw has a built-in depth cut feature you can use to vary the depth of cut of the saw blade.

This comes very useful when you have to make preliminary cuts to improve the accuracy, neatness or quality of the cut, and to ensure safety.

Overall, the Makita SP6000J1 come equipped with top of the line features you need in any track saw.

2. Dewalt DCS520T1 60V Cordless Track Saw Kit

Make straight splinter-free cuts through hardwoods as thick as 2-1/8 inch with ease using the Dewalt DCS520ST1 60 Volts cordless track saw.

Equipped with a powerful brushless motor backed by Dewalts 60 Volts Flexvolt battery system, you get a powerful cordless plunge-cutting machine with enough run-time to complete heaps of cuts in one charge.

The zero clearance track or guide rail ensures every cut you make is straight, precise and free of splinters.

Not limited to 90 degree cuts, you can also make bevel cuts up to 45 degrees at a max depth of 1-5/8 inches.

Wide materials tends to bind with the blade when making rip cuts, that’s why this one is fitted with a riving knife to prevent binding and kickbacks from happening when making a cut.

In fact, Dewalt’s track saws are only one of the few among the competition that have this very important safety feature.

Dust collection is a breeze as the saw comes fitted with 1-1/4 inch dust ports onto which you can hook up your vacuum to keep sawdust in its place when making cuts.

All in all, if you really want a cordless track saw that’s designed to take care of special rip-cutting and plunge-cutting applications both on and off the jobsite, then you should seriously consider getting this Dewalt DCS520ST1.

What we like about it

Where we don’t like

3. Bosch GKT13-225L

Bosch needs no introduction when it comes to tools such as this. When you use the Bosch GKT13-225L, you’d easily see why we think so.

Every feature of the tool is engineered to ensure your cuts come out as straight and accurate as possible.

It’s a 13 Amp corded track saw capable of producing variable speeds from 3600 to 6250 RPM. The 6-1/2 inch blade spins at that much speed to help you produce the best quality cuts on the hardest of woods.

You can make bevel cuts from -1 to 47 degrees with a single bevel point when using the track or guide rail compatible with it.

No matter how hard or demanding the material is, the saw’s constant electronics feature ensures the blade spins at a constant speed to allow you get the results you need.

It also has an overload protection feature which prevents the motor from overheating while making cuts.

Changing blades is a quick 3-step process and dust collection is also easy once it’s hooked to a compatible shop vac.

What we like about it

Where we don’t like

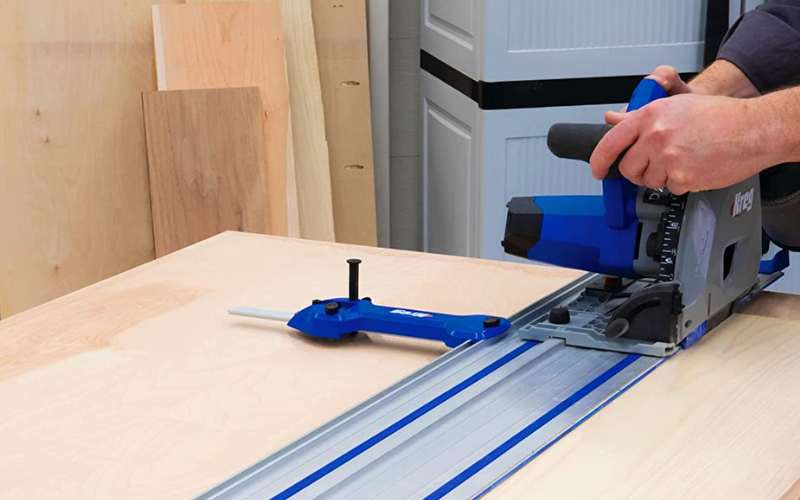

4. Kreg Adaptive Cutting System

The Kreg Adaptive Cutting System is a track-guided circular saw you can use for cutting materials with accuracy and precision.

Combined with their 62 inch guide track, you can plunge-cut plywood, solid wood and other materias with it with great accuracy.

The saw comes equipped with a 12 amp 120 volt variable speed motor which spins the saw blade at a no-load speed within the range of 2000 to 5500 RPM.

With it, you can cut boards as thick as 2-1/8 inches at 90 degrees and you can make bevel cuts through 1-1/2 inch thick materials at 45 degrees.

It comes with important safety features like a riving knife that prevents binding and kickbacks and an electronic break to halt the blade rotation once you’re done cutting with it.

You can make bevel cuts from -1 degrees to 47 degrees which makes it ideal for a whole lot of applications.

What we like about it

Where we don’t like

5. WEN CT1065 Sidewinder Plunge-Cut Circular Track Saw

If you don’t have the budget to go for the high end models, WEN produces a very budget friendly track saw you can get without altering the weight of your wallet.

The WEN CT1065 track saw can rip 2-1/3 inch thick boards in one pass at 90 degrees and 1-5/8 thick boards at 45 degrees.

If you want to make long rip cuts or internal rip cuts, this is one of the best saws you should get. It comes equipped with a 6-1/2 inch 24 tooth carbide-tipped blade, but you can always upgrade the blade to get even finer cuts from this machine.

At the heart of the saw is a powerful 10-amp motor capable of spinning the blade at 5500 RPM, cutting cleanly and precisely through the hardest of sheet woods, even engineered lumber.

Three blade settings allow you to make 1/8 inch deep scoring cuts, plunge cuts and for easily swapping out the blade for a new one.

Overall, this WEN track saw comes with just the right features to pitch it among the best track saw you can use for your projects.

What we like about it

Where we don’t like

6. Festool TS 75 EQ Plunge-Cut Saw

If you don’t want to compromise in cut quality, and all you want is pin-point accuracy with no room for errors, then the track saw you should probably go for is this one from Festool.

It’s the FESTOOL TS 75 EQ Plunge-Cut track saw. Remember, they also have the TS 55 REQ track saw, but this one here is better than that one.

While the TS 55 comes with a 55 inch track or guide rail for the saw, this one comes with a 75 inch track to enable you rip through and break down the largest of sheet materials.

You can find every feature of the TS 55 in this TS 75. Features such as the spring-loaded riving knife for preventing binding and kickbacks, and the FastFix system which enables locks the saw switch and arbor simultaneously to allow you swap out blades easily.

To further prevent or minimize any chances of kickbacks occurring, the saw also comes with a slip clutch, which in addition to that helps minimize wear on the saw blade, motor and gear case.

With a saw blade diameter of 8-1/4 inches, you can use the TS 75 EQ to cut through materials as thick as 3 inches when making 90 degree cuts and 2-1/8 inches when making 45 degree bevel cuts.

It has a bevel capacity of 0 to 47 degrees and consumes up 1600 Watts of power.

All in all, when you’re looking for a top quality track saw to tackle projects such as breaking down large sheet materials, trimming rough lumber, cutting solid doors and window frames, this is the saw you need.

It will tackle those projects and some more with pinpoint accuracy.

What we like about it

Where we don’t like

You must be (censored word) to name Makita No1. It is miles out on accuracy, blades do not last either.. How can you rate it above Dewalt and Festool. Makita must be paying for this review 😀

There’s no place in this article where I said Makita is the best. Instead, I wrote “it’s one of the best”.

The numbering in our reviews don’t represent hierarchy from Number 1 to 10. It’s just a list of the best track saws you can choose from. The best in the list can be in number 10, number 4, number 7 or any number. There is no hierarchy. They’re not numbered from best to worst or from worst to best. Number 10 is not the worst, and number 1 is not necessarily the best.

You just have to go through the article, through the 10 listed here and choose the one most suitable to your needs. People have different needs. Some need a budget friendly one for simple DIY projects, some need the one with the most power due to the type of materials they want to cut, others favor ergonomics – weight, dust collection and so on. Some even go after a certain brand, whether it performs poorly or not. That’s why you need to go through the 10 listed and choose according to your needs and according to your budget. Again, number 1 on this list is not necessarily the best one.

Thanks for your comment.